Our Business

Arla Plast is a leading producer and supplier of extruded sheets made of technical plastics. Our plastic sheets have a wide range of applications such as personal protection, machine guards, ice hockey rinks, automotive parts, sound walls and greenhouses.

Arla Plast's corporate culture and business operations are steeped in values based on quality, speed, service and flexibility, which are our four cornerstones. Extensive experience, an emphasis on sustainability, a high level of investment and advanced extrusion technology ensure that Arla Plast is well positioned in the industry.

The company was founded in 1969 and has four production facilities in Sweden, the Czech Republic and Spain, as well as a distribution unit in Germany, around 350 employees, and more than 700 customers in over 45 countries. The head office is located in Borensberg, Sweden, and the company’s shares have been listed on Nasdaq Stockholm since 2021.

Production

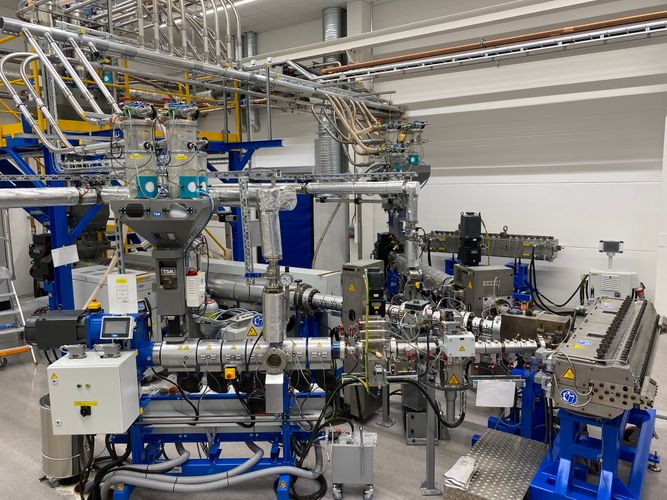

Arla Plast’s production begins with the purchase of various plastic granules from producers of this material. The main raw materials are supplemented with recycled material. Various materials such as color additives (“master batches”), UV protection and other additives are then added to achieve the desired properties. The plastic granules of PC, ABS, PETG or PMMA are dosed in at the beginning of the extrusion process and heated to melt the plastic. The melt is screwed forward through a barrel to a wide nozzle and shaped into a sheet. The plastic sheets are then coated with a protective film and cut into standard or customer-specific sizes, a common size is two by three meters. Pallets are transported to customers by truck or container.

Sales and distribution

Sales are made through regional sales offices across Europe. Sales representatives have overall responsibility for managing existing customers and initiating contact with new clients. Orders are placed through customer service functions within the Group. The plastic sheets are distributed through a network of forwarders to ensure efficient deliveries within set timeframes.